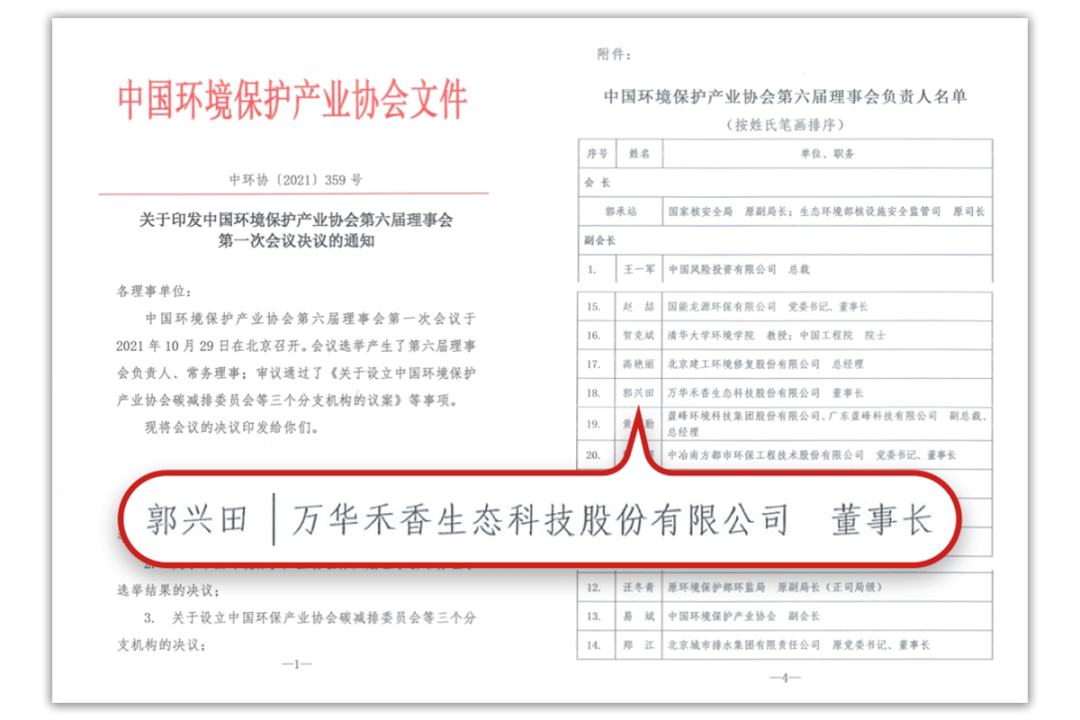

Chairman Guo Xingtian Elected as Executive Director and Vice President of the China Environmental Protection Industry Association

Recently, the China Environmental Protection Industry Association held a re-election. Guo Xingtian, Chairman of Wanhua Hexiang Eco-Technology Co., Ltd. (referred to as Wanhua Eco), was elected as the Executive Director and Vice President of the China Environmental Protection Industry Association..

Advocate of Ecological Civilization

Pioneer of Green Panels

As a pioneer balancing economic development and a sound ecological environment,Wanhua Ecohas started from tackling indoor formaldehyde pollution, gone through the fields of recycling agricultural and forestry residues, distributed industrial cluster intelligent manufacturing, green industrialized customized home furnishing, and distributed rooftop photovoltaic power generation,and has been steadfastly committed to the path of green sustainable development and environmental protection for more than 20 years.

As early as 2000, in response to the then formaldehyde pollution in China, Wanhua promoted the replacement of urea-formaldehyde adhesives with formaldehyde-free adhesives, achieving the goal of "Under the roof, there should be no formaldehyde". In the process of tackling indoor air pollution, it was found that as the world's largest furniture factory, China cuts down at least 600 million cubic meters of natural forest every year, more than the reserves of the Greater Khingan Mountains. At the same time, 1.7 billion tons of rice/wheat straw and other agricultural and forestry residues are burned every year due to lack of disposal, causing serious air pollution.

Based on its scientific research strength, Wanhua Eco started the research and development of straw-based man-made boards with the concept of "turning waste into treasure, using grass instead of wood", and officially established Wanhua Eco Board Industry Company in 2006. The formaldehyde-free straw-based man-made board production technology developed by the company won the National Science and Technology Progress Award (Second Prize). On the basis of straw-based Hexiang board, the company also successfully put into production fruitwood (board) made from fruit tree branches and other materials. In 2018, when President Xi Jinping inspected Wanhua Chemical Yantai Industrial Park, he praised it as a "good product beneficial to the country and the people".

Wheat/rice straw, reeds, cotton/tobacco stalks, branches and other fiber-rich agricultural and forestry residues provide abundant renewable raw materials for Wanhua's green formaldehyde-free man-made boards. Nowadays, Wanhua Eco also cooperates with local governments to plant fast-growing plants such as "reed bamboo" in the Yellow River beach and wasteland, which not only achieves water and soil conservation and improves the ecological environment, but also increases farmers' and fiscal income, and enhances carbon absorption capacity, practicing the concept that "lucid waters and lush mountains are invaluable assets".

According to preliminary estimates,for every 1 cubic meter of agricultural and forestry residue-based man-made board produced, 1.18 tons of agricultural and forestry residues can be solidified; 1.2 cubic meters less forest is cut, and 1.473 tons more carbon is absorbed; after deducting 0.196 tons of carbon generated during the production process,a final carbon emission reduction of 1.425 tons is achieved, which can be used for carbon trading.

In 2015, Wanhua Eco repositioned itself as a green home furnishing industry ecosystem operator, building a green industry ecosystem "from the source, based on home, and ecological cycle". With "one drop of glue (MDI glue), two boards (Hexiang board/fruitwood)" as the foundation, the industrial chain extends forward to "three types of cabinets (custom furniture)" with Industry 4.0 collaborative intelligent manufacturing, and then to "new home furnishing (Sikong green industrialized customized home furnishing)" in the stage of "industrialization, digitalization, and greening" of the home furnishing industry Internet ecosystem reconstruction.

The green industrialized customized home furnishing of "fast, beautiful, and green" not only realizes the productization and reconstruction of home decoration, making "everyone can do decoration" and "decorate whenever you want", lowering the entry and consumption threshold of the industry, but also conforms to the development trend of prefabricated buildings and interior decoration. Personalized customization greatly reduces the generation of construction waste caused by demolition and on-site processing, reduces the demand for high-energy-consuming building materials such as cement, and thus indirectly promotes carbon emission reduction.

The wide distribution of raw materials, transportation economy, and high efficiency of local services determine the feasibility of distributed industrial cluster layout. At present, Wanhua Eco is cooperating with governments at all levels in Shandong, Henan, Anhui, Hunan, Hubei, etc., with formaldehyde-free man-made board factories using German Dieffenbacher large-scale continuous flat pressing line equipment as the core, to promote the construction of distributed green industrial cluster industrial parks.Through the intensive and large-scale, intelligent and customized full industry chain and value chain reconstruction of home furnishing, high-quality and low-cost green industrialized customized home furnishing is realized,solving many stubborn problems in the supply chain such as uniformity of finished decoration, transportation, damage, cost, and efficiency, and also indirectly promoting carbon emission reduction.

At present, 12 core factories and 1 distributed green dual-carbon industrial cluster demonstration park (Jingmen, Hubei) have been put into operation or are under construction. It is planned to complete the construction of 20 distributed green dual-carbon industrial cluster industrial parks nationwide by 2025.By then, Wanhua Hexiang Board Industry will also become the world's unicorn in all categories of green man-made boards, with an initial annual production capacity of 5 million cubic metersand at least 7.125 million tons of annual carbon emission reduction. At the same time, the Sikong new home furnishing service will cover a radius of 300 kilometers in major population gathering areas across the country. With these achievements, the company practices the development goals of "green manufacturing, intelligent manufacturing" in "Made in China 2025", realizes the transformation of new and old kinetic energy and structural labor skills, and expands employment coverage.

In January 2021, the distributed rooftop photovoltaic power generation project of Wanhua Hexiang Board Industry (Tongling) factory was accepted and delivered, achieving a total grid-connected capacity of 11.8MW (megawatts), with self-use and surplus electricity supplied to the grid. According to the plan, only the distributed rooftop photovoltaic power generation of 20 core factories under Wanhua Hexiang Board Industrywill reach 190 MW (megawatts) by 2026, with an annual carbon emission reduction of 209,000 tons.

Taking advantage of the ecological system of distributed industrial clusters, Wanhua Eco is exploring the recycling and reuse of solid waste such as old furniture and construction waste. It has signed a recycling agreement for office furniture disposal with the central administrative institution's state-owned asset disposal platform. After achieving preliminary results in pilot areas, it will be promoted in all service coverage areas.

"No harm to humans, no damage to nature, no danger to society" is the ecological development philosophy of harmony between man and nature pursued by Wanhua Eco, and the company is striving for this dream.