Wanhua Lingquan Formaldehyde-free Gypsum | Leveling and Joint Filling Are Different

What are the differences between leveling gypsum and joint gypsum, since both are gypsum? Where should each be used? Let's find out together today.

Wanhua Lingquan Formaldehyde-Free Leveling Gypsum

Different Application Scenarios

Leveling Gypsum

is a base plastering material for interior walls, suitable for wall skimming. In addition to requiring certain adhesion, crack resistance, and filling properties, it also needs smoothness for large-area application (water retention). Leveling gypsum is suitable for base plaster leveling of concrete, aerated concrete, and brick-mortar walls.

Joint Gypsum

has finer aggregate, mainly used for filling grooves and joints, suitable for repairing indoor holes, grooves, and gaps, and also for local leveling of relatively flat concrete, brick-mortar walls, and ceilings. Note that its application area is relatively small and it is not suitable for joint repairs with a width less than 2mm; large-area use may cause local cracking and peeling. Compared to the smoothness of leveling gypsum, joint gypsum values adhesion, strength, and crack resistance more.

Different Product Composition

Leveling Gypsum

is a sand-type base plastering material for interior walls, made by mixing gypsum, graded sand, and various additives.

- Gypsum: High-strength, precision gypsum powder.

- Graded sand: Different particle sizes to enhance product stability.

Joint Gypsum

is a wall repair material made mainly from gypsum and various additives.

- Gypsum: High-strength, precision gypsum powder.

- Retarder: Construction gypsum sets quickly when mixed with water, usually within a few or a dozen minutes. To facilitate operation, a suitable retarder is needed to adjust the initial setting time.

- Water-retaining agent: To prevent joint gypsum from losing water during construction, which would affect full hydration, reduce bonding strength, and cause cracks, a water-retaining agent is added to improve water retention.

- Polymer: To prevent cracks caused by the brittleness of gypsum during construction and use, organic polymers are added to improve its flexibility.

- Filler: Improves the density of joint gypsum, making it finer.

Wanhua Lingquan Formaldehyde-Free Leveling Gypsum, Joint Gypsum

Wanhua Lingquan Formaldehyde-Free Leveling Gypsum WHBM3001

Using Wanhua formaldehyde-free technology, water-based and environmentally friendly, without the addition of formaldehyde, benzene, or their derivatives. It is a coarse sand-type base plastering material for interior walls, made by mixing gypsum, washed sand, calcium carbonate, and various additives. Suitable for base plaster leveling of concrete, aerated concrete, and brick-mortar walls.

Construction Process and Precautions

1. Substrate Treatment

2. Add Water

3. Mixing

4. Plastering

5. Leveling

6. Completion

Substrate Cleaning:

The base should be solid, free of dust and dirt, and the wall surface moisture content should not be less than 5%. If the base is smooth or loose, interface treatment or cement roughening is required.

Water Addition and Mixing:

Theoretical water addition is 26%-30%. The actual amount should be based on construction consistency. After mixing evenly, let it stand for about 5 minutes, then mix again before use. The slurry mixed at one time should be used up within the usable time. Do not add water to the initially set slurry for reuse.

Plastering and Leveling:

Each plastering thickness should be controlled between 2mm-5mm. If a greater leveling thickness is required, it should be done in multiple layers.

Construction Temperature:

The construction environment temperature should be above 5°C, and the curing process temperature should not be lower than 0°C.

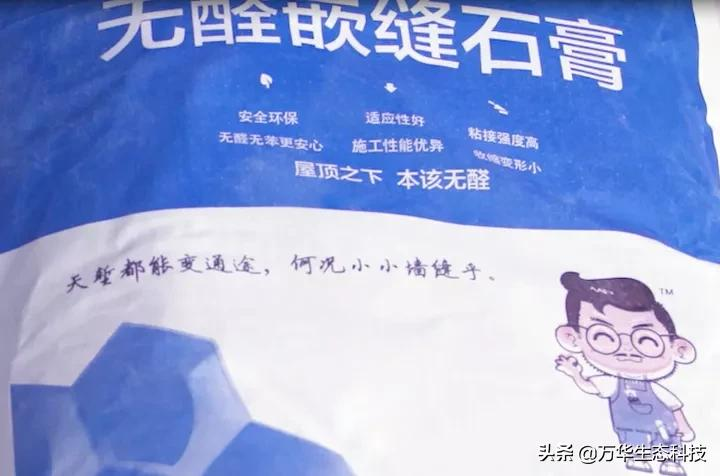

Wanhua Lingquan Formaldehyde-Free Joint Gypsum WHBM3002

Using Wanhua formaldehyde-free technology, safe and environmentally friendly, without the addition of formaldehyde, benzene, or their derivatives. It is a wall repair material made mainly from gypsum and various additives.

Suitable for repairing indoor holes, grooves, and gaps, as well as for local leveling of relatively flat concrete, brick-mortar walls, and ceilings. Not suitable for joint repairs with a width less than 2mm.

Construction Process and Precautions

1. Substrate Cleaning

2. Mixing

3. Repairing Joints

4. Completion

1. Substrate Cleaning:

The base should be solid, free of dust and dirt, and not loose.

2. Mixing:

Mix to the required consistency for construction, mix evenly, let it stand for 2-3 minutes, then mix again before use.

3. Construction Notes:

The width of joint repairs should be controlled above 2mm,

Plastering thickness should be controlled between 2mm-3mm,

The mixed paste should be used up at once,

Avoid hardening and scrapping.

4. Construction Temperature:

The construction environment and curing process temperature should be controlled above 5°C.